This is an old revision of the document!

Unipi Extensions

Looking for a guide to connect the extensions to Neuron or Axon controllers? Please visit this detailed tutorial.

The Extension line is designed as a simple and cheap method of automation systems expansion by adding more I/Os without the need to purchase new controllers. Extension modules are communicating with the PLC over the RS485 serial line and albeit they are designed primarily for the use with Neuron controllers, they can be used in combination with any PLC supporting the RS485 serial line and Modbus protocol. That makes the xS-line an excellent choice for cases where other PLC manufacturers either do not offer their native extension, or their purchase would be cost-ineffective.<hidden>

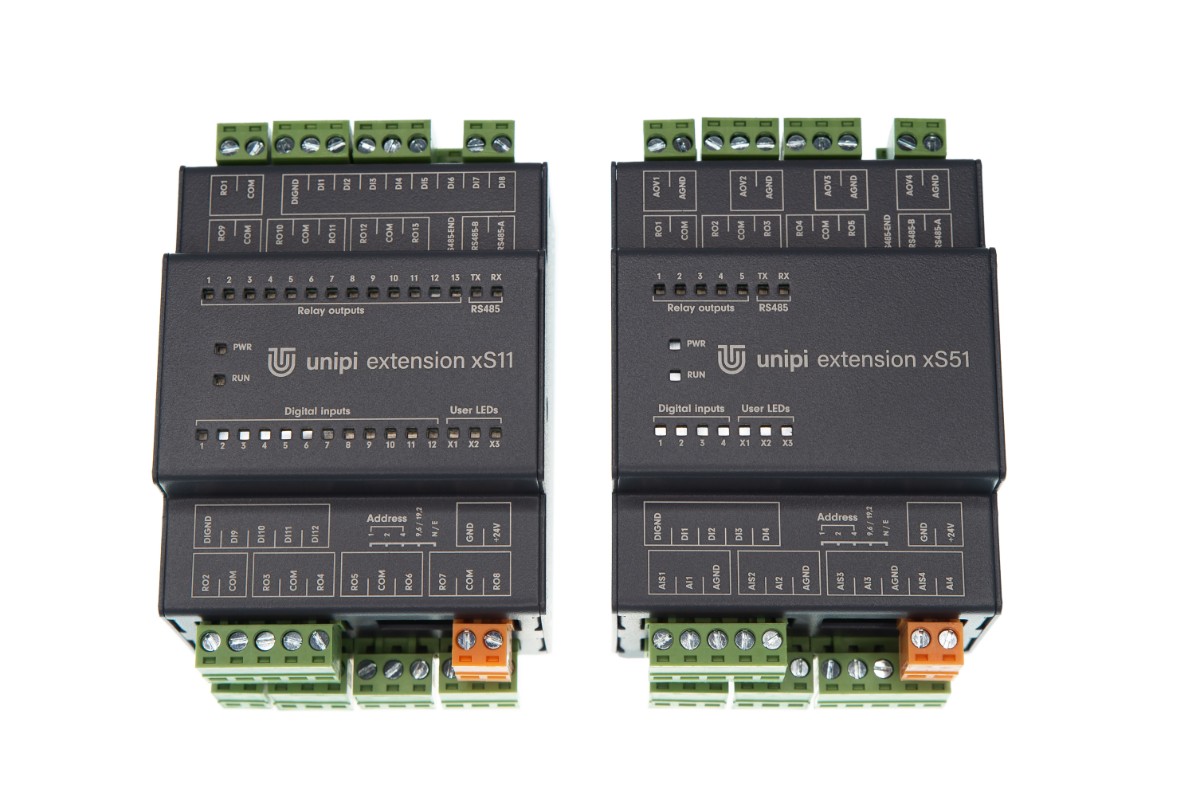

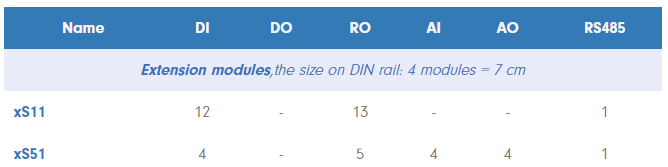

Unipi Extension model overview

Connection to Unipi controllers

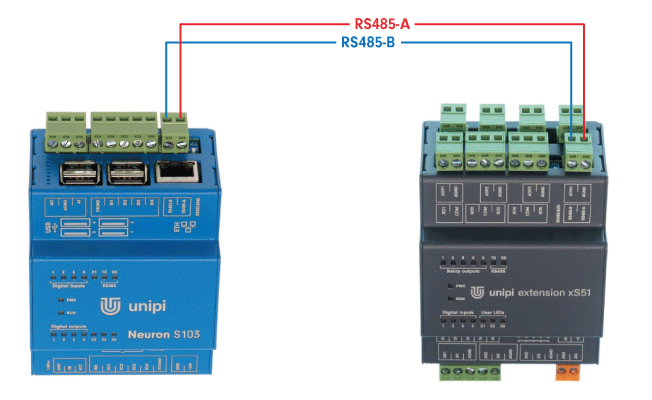

You need only two cables to connect the Unipi extension to the controller. Just interconnect the RS485-A port on the controller to RS485-A port on the extension and RS485-B on the controller to RS485-B on the extension.

Examples of usage

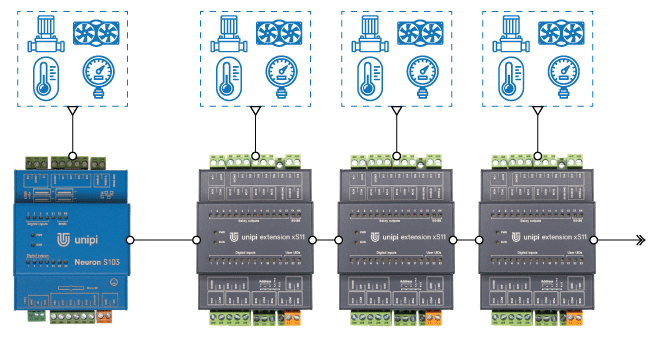

Unipi Extension modules are a simple and inexpensive solution in cases your PLC's I/O number is no longer sufficient. Modules are managed by a control logic running on the PLC, and as such don't require any programming. Multiple extensions can be placed on a single bus, allowing you to create a network of modules with a very high number of I/Os, controlled by a single PLC.

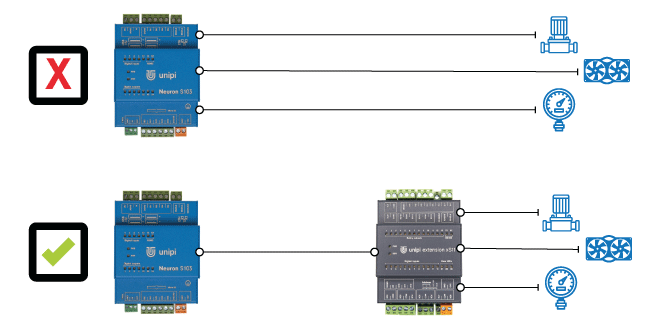

Alternatively, you can use the extension modules to make inputs and outputs accessible in installations located away from the central distribution box with the PLC (ie. next room, another storey etc.). You can simply install the extension in the remote location, connect all devices you want to control or monitor, and then connect the extension to the PLC using only a pair of serial cables. This solution significantly decreases the amount of needed cabling, reducing the expenses considerably.

Special functions

Configuration of communication parameters and addressing

There are two ways to change the configuration:

- HW configuration - using DIP switches

- SW cofiguration - using Modbus

Restart/Power cycle is always needed to apply new configuration usign any of the method.

HW configuration

The easiest way to configure the communication parameters. Allows limited configuration options.

SW configuration

Used only when the Modbus Address configured via DIP swiches is set to 0. Useful when the options that the HW cofiguration provides is not enough.