This is an old revision of the document!

Data source

Data source is a simplified definition of a PLC used in another solution. The basis of the definition are the communication parameters for connection to the PLC (local or proxy) and the *.exs file containing the definition of variables.

This solution is suitable for use where it is necessary to connect several previously separate solutions that have been created either by the interaction of several programmers or by splitting an already too large assembly.

The data source can be used for communication via SSCP protocol, webserver or Mervis SCADA.

It is recommended to have the solution in Full mode before continue.

Adding a data source to the solution

Adding a data source to the solution is done by selecting the System line at the top of the left solution panel, right-clicking and selecting Add Data Source from the context menu.

The Data Source item will be added to the solution.

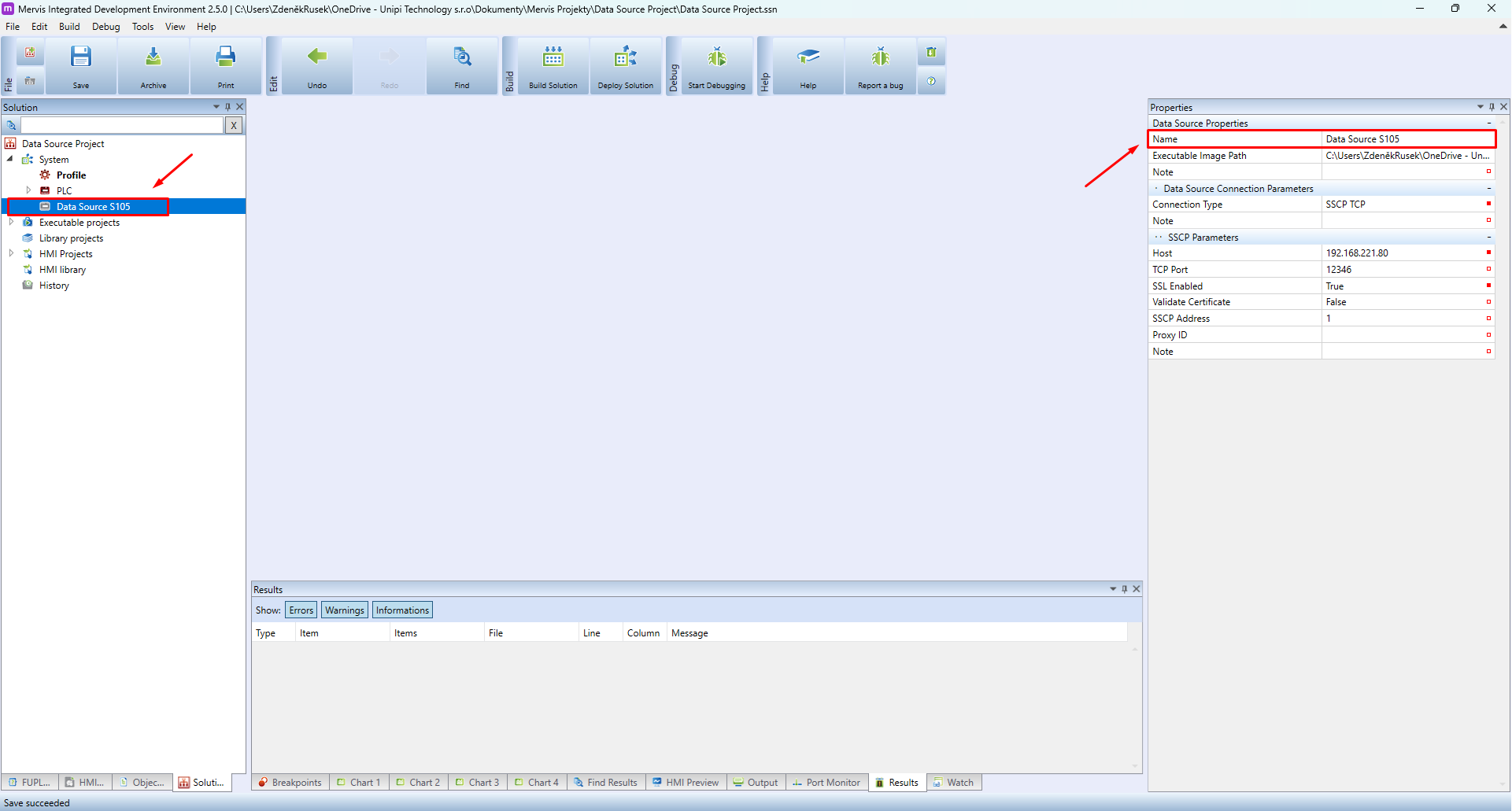

Names

It is almost impossible to identify the PLC used in the data source, so it is advisable to set a descriptive name for the data source and include information about the source assembly (name, version, compile date, etc.) in a note. Both can be set in the properties in the right panel. In the sample solution the data source was named after the source PLC (Axon S105).

Setting properties

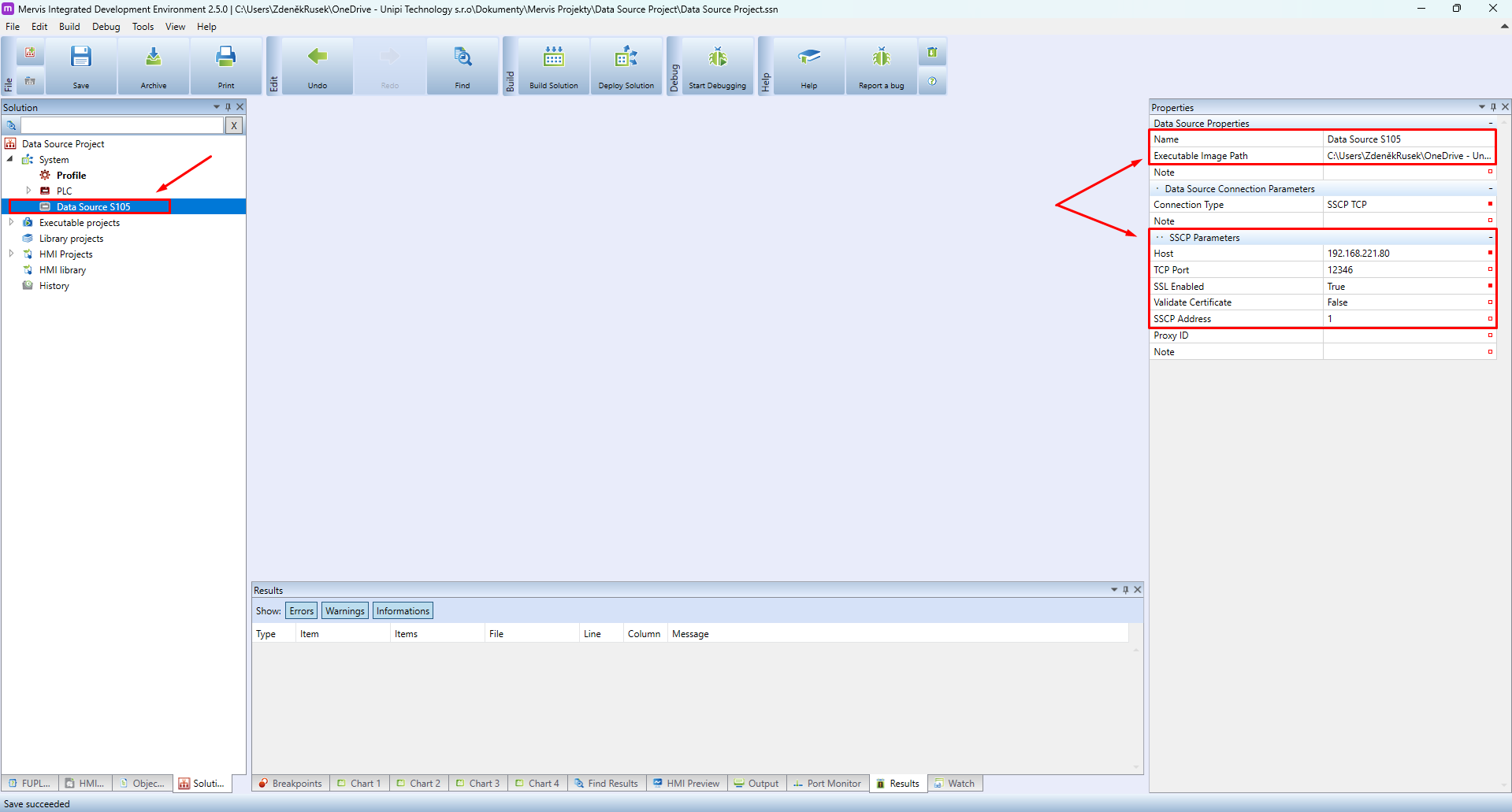

For each data source, you must define SSCP parameters for communication, which vary by application.

Local

Local use means the connection of the PLC on the same local area network (LAN). Locally, the data source can be used for communication via SSCP protocol, or for connection to external web terminal. On the other hand, a locally defined data source cannot be used for a SCADA terminal because the SCADA server is not running on the local network but in the cloud.

For local communication, the IP address and a few other parameters available in the source solution are sufficient.

- Target address: IP address of the source PLC

- TCP port: 12346 (12347 for SSL)

- SSCP address: usually 1

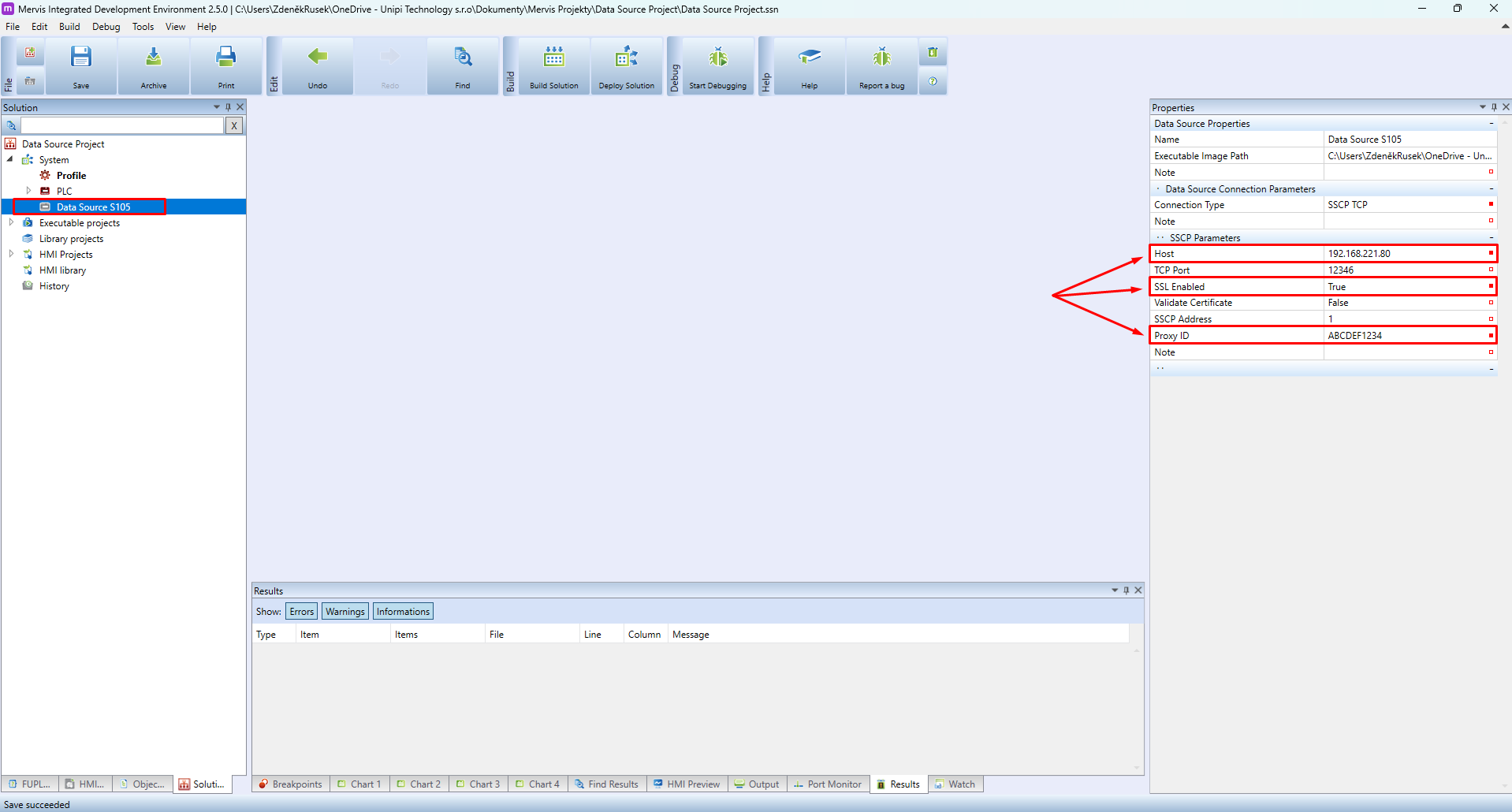

Proxy

Connecting a data source is also possible via Mervis Proxy. Connecting via proxy is ideal for merging multiple PLCs into one SCADA project, or for exchanging information via SSCP protocol in a large facility where individual PLCs are either on separate networks or connected via LTE network.

The connection to the proxy server must be active on the source PLC. The proxy setup is described in separate article.

To connect via Mervis Proxy, you must set the following in the data source properties:

- Target address: proxy.unipi.technology

- TCP port: 12348 (12349 for SSL)

- Certificate validation: for SSL only, details here

- SSCP address: mostly 1

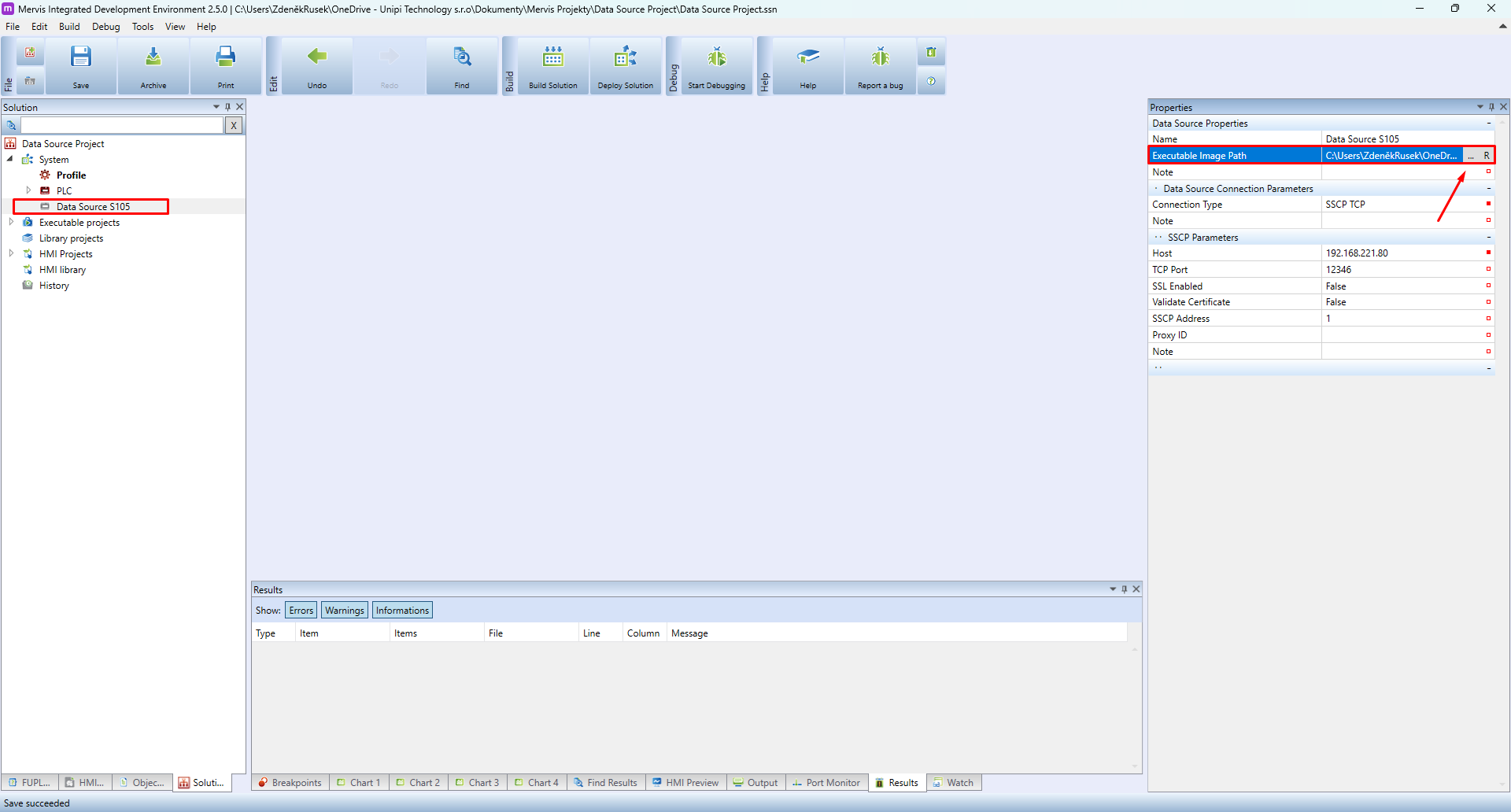

.exs file

In general, an .exs file is an executable copy (Shark Executable Image) of a project in the Mervis IDE. In this case we can say that it is the definition of all variables that are available in the PLC (inputs, outputs, in the program). This file is generated among the solution files in the bin directory, every time the assembly is compiled.

First you need to select the data source in the left panel of the solution, which will display the data source properties in the right panel. In the properties, the *.exs file from the selected assembly is selected for the “Path to executable image” parameter:

WARNING! When moving solution folders, it is necessary to take extra care not to disconnect the *.exs file, or take this into account and create the link again. Otherwise, you will not be able to compile the report or work with the data source variables.

Usage

SSCP communication

Whatever the reason for using the data source, the SSCP protocol can also be used for data exchange between PLCs. More information can be found in the separate article Controlling a PLC through SSCP protocol from another PLC.

SCADA

Adding PLCs to Mervis SCADA is possible thanks to the data source without having to merge them into one large assembly. This is especially advantageous for maintaining clarity, logical partitioning, or if each PLC is managed/programmed by a different programmer. This use is explained in detail in 029-merging-few-projects-under-one-mervis-scada.

Webserver

It is possible to connect a data source similar to a PLC to a local web HMI that is created as a webserver terminal and display information from this PLC from another report. Further information can be found in the separate article Creating a HMI for an external PLC webserver.